No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

BWLE-4040 4" x 40" Reverse Osmosis Membrane, 2600 GPD for Commercial, Industrial and Agricultural Water Desalination

MEMRO4040XLE

New

BWLE-4040 4" x 40" Reverse Osmosis Membrane, 2600 GPD | Ultra Low Pressure 4040 for Commercial, Industrial and Agricultural Water Desalination

- Ultra Low Pressure 100 psi

- High Production Flow Rate 2600 GPD

- Highly Stabilized Rejection with Nominal Flow Obtained

31 Items

Available

BWLE-4040 4" x 40" 2600 GPD Reverse Osmosis Membrane | Ultra Low Pressure 4040 for Commercial, Industrial and Agricultural Water Desalination

Industrial Reverse Osmosis Membrane manufactured by one of the world's top membrane manufacturers HIDTM . Each membrane is made from pre-developed and pre-screened sheets and goes through strict manufacturing processes as well as internal quality inspections and testing. SGS certified membrane for drinking water.

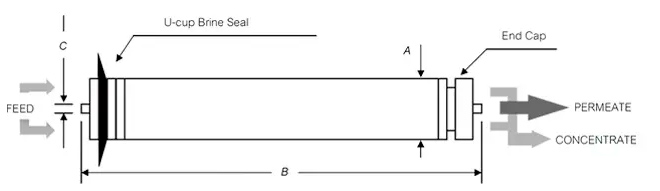

Dimensions Membranes de ósmosis inversa industriales HIDTM - Serie 4040:

Model No. | A (inch/mm) | B (inch/mm) | C (inch/mm) |

BWLE-4040 | 4.0/100.1 | 40/1016 | 0.75/19.1 |

4040 Series Seawater Reverse Osmosis Membranes are widely used for commercial, industrial and agricultural water desalination.

| Model No. | Feed Spacer Thickness (mil) | Mi. Salt Rejection (%) | Stabilized Salt Rejection (%) | Permeate Flow Rate (GPD) | Test Pressure (psi) | Test Water TDS (mg/l) |

| BWXLE-4040 | 28 | 97,5 | 98 | 2600 | 100 | 750 |

| N º de Modelo. | Maximum Operating Temperature | Maximum Operating Pressure | Feed Water pH Range Continuous Operation* | Maximum Feed Water Turbidity | Maximum Feed Water IDE | Chlorine Tolerance |

| BWXLE-4040 | 45 ℃ | 300 psi | 2-11 | 1NTU | 5 | |

-

Pack 4 Water Filters for Universal Reverse Osmosis 5 stages

Pack 4 Water Filters for Universal...

£ 14.76 -60% £ 36.91